PRODUCTS

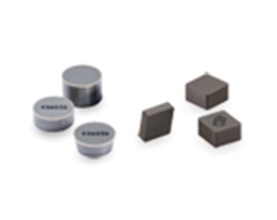

PCD / CBN / Ceramic

- KBN010 / KBN020

- New coating + high-content CBN provides both Wear Resistance and Fracture Resistance. The new coating covers a wide range of application machining, achieves long tool life and stable machining of hardened material.

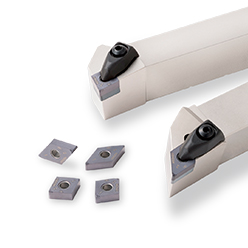

- AGT Chipbreaker

- Stable machining for various aluminum alloy machining applications. Unique chipbreaker provides excellent chip control.

- APD Chipbreaker

- Superior chip control when machining aluminum. Newly designed molded chipbreaker controls chips.

- H Chipbreaker Series

- Molded chipbreaker provides excellent chip control when machining hardened material. 3 chipbreaker Styles are available.

- KS6015/KS6050/CS7050

- Silicon Nitride Ceramic for Cast Iron. Efficient and Reliable Cast Iron Machining.

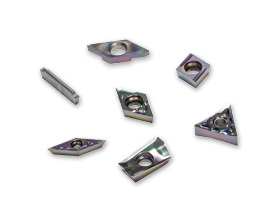

- PDL010

- DLC coating for high quality and longer tool life for aluminum machining

- PDL025

- DLC coat for high quality and long tool life in Aluminium machining

- KBN475

- Applicable to high speed machining for cast iron. Longer tool life by excellent wear resistance.

- KBN05M

- Hardened steel and high hardness material machining CBN grades. Excellent fracture resistance of two new technologies, the wear resistance is achieved

- KBN570

- Iron-based sintered metal working CBN grades. And suppress the burr with sharp edge specification

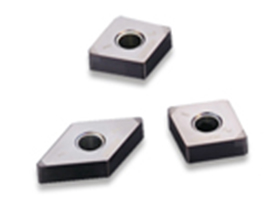

- KPD001

- Super micro grain polycrystalline diamond tool. Both of high wear resistance and high fracture resistance

- KS6030 / KS6040

- SiAlON ceramic grades for heat-resistant alloy machining. The high reliability and stable machining

- PT600M

- Ceramic grades for high hardness material machining. Achieve a long tool life of approaching the CBN by adopting MEGACOAT